In the wire and cable manufacturing and processing industry, coiling density is a key metric for measuring cable coiling quality. Appropriate coiling density ensures cables remain undamaged during transportation and storage and prevents tangling during use. So, how do cable coiling machines achieve precise control over this coiling density? This article delves into the core technical principles.

Core Technical Mechanisms

1. Adjustable Tension Control System

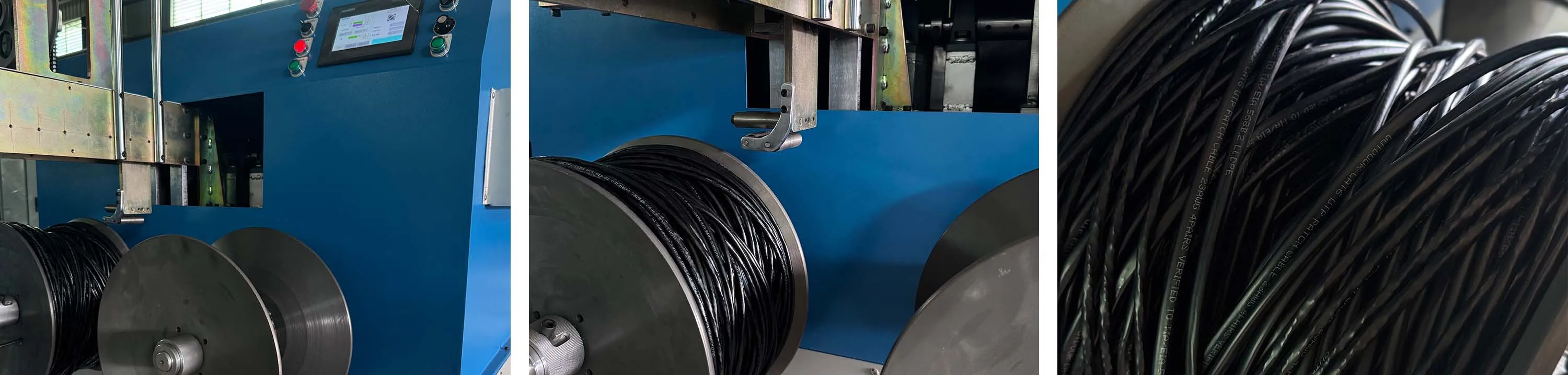

Cable coiling machines utilize precise tension control devices to adjust the pulling force during the coiling process. For cables of different specifications—from thin data cables to thick power cables—operators can set corresponding tension parameters accurately. This adjustment ensures the cable is neither too loose (causing disorder) nor too tight (causing damage).

2. Intelligent Speed Regulation

The coiling speed directly affects the lay of the cable. Our equipment is fitted with a stepless speed control system, allowing precise adjustment of the operating speed based on the cable type and coiling density requirements. For high-density coiling needs, reducing the speed allows more time for each turn to be positioned properly; for standard requirements, the speed can be increased to optimize production efficiency.

3. Specialized Spool/Reel Design

The structural design of the spool or reel plays a decisive role in coiling uniformity. We offer a variety of standard spool accessories, each engineered and tested to ensure the cable distributes evenly across the entire spool, preventing localized overtightening or looseness.

4. Real-Time Monitoring and Automatic Correction

An advanced sensor system continuously monitors various parameters during the coiling process, including tension stability and cable alignment. Upon detecting any deviation, the system immediately auto-adjusts the relevant parameters to ensure consistency in coiling density. This intelligent closed-loop control system significantly reduces the need for manual intervention.

Application-Specific Solutions

Power Cables: Utilize higher tension settings and medium coiling speeds to ensure secure winding of heavy cables.

Data Cables: Employ lower tension control and variable speed settings to protect delicate internal conductors from damage.

Automotive Wiring Harnesses: Combine specialized reel designs with precise tension control to meet the high standards of the automotive industry.

Technical Advantages

Our cable coiling machines integrate precision mechanical engineering with intelligent control technology, providing a comprehensive coiling density solution:

Customizable parameters to adapt to different industry needs.

User-friendly operating interface for simple and intuitive adjustments.

Stable long-term operation with low maintenance costs.

Conclusion

Coiling density control is a critical step in the cable processing workflow, directly impacting product quality and usability. Through continuous technological innovation and process optimization, our cable coiling machines deliver perfect coiling solutions, helping enterprises enhance product quality and market competitiveness.

To learn how our cable coiling machines can meet your specific requirements, please feel free to contact our technical team for a personalized solution.