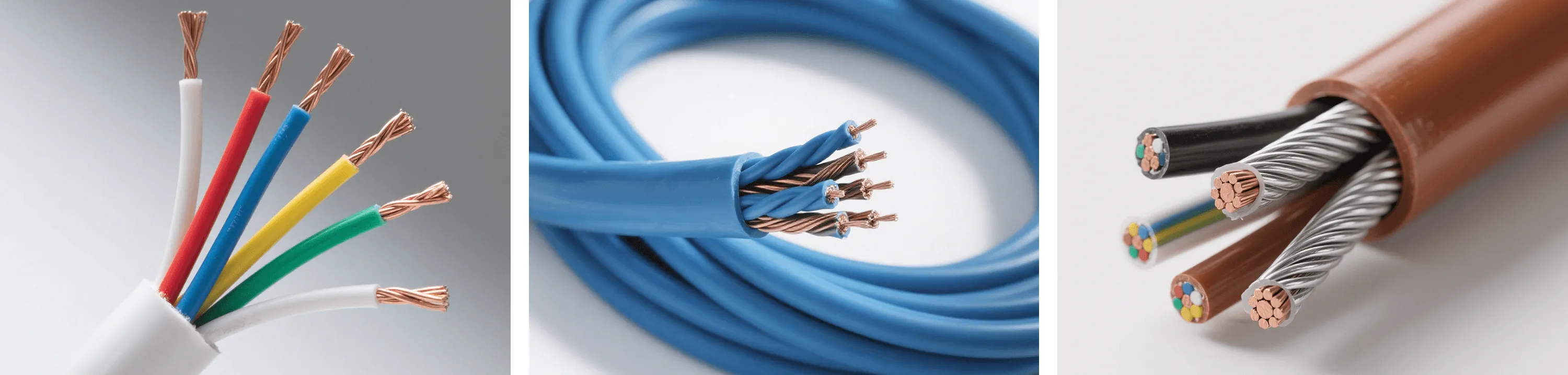

The power in your home, data on your phone, and factory machines all rely on hidden "lifelines": wires and cables. How are these vital parts of modern life created? Let’s look at the key steps:

The Core: Conductor

It starts with flexible copper or aluminum conductors – the "highways" for current or signals.The Vital Shield: Insulation

Bare wires are dangerous! A layer of insulation (like PVC or PE) is essential for safety and performance. How is it applied perfectly? With high-precision Core Wire Insulation Extrusion Lines, the "coating experts" that ensure reliable, risk-free transmission. (Special foaming boosts data cable performance).Strength & Structure: Stranding

Multi-core cables (like power cords or network cables) need their insulated wires twisted together ("stranding"). This builds strength and improves performance (e.g., less signal noise). Precision Stranding Machines provide the stable "backbone".The Outer Armor: Sheath

A tough outer layer (like PVC) protects the cable from damage, weather, and chemicals.

Precision Builds Reliability

Every safe, efficient cable relies on mastering these processes. High-quality insulation extrusion ensures safety, while precise stranding creates the core structure.

Professional equipment is key to making cables that meet demanding needs. These machines are the unsung heroes building the "lifelines" powering our world.

Discover the core equipment: Explore Solutions.