Published Date: January 19, 2026Author: Engineer Li (Senior Mechanical Engineer, Dongguan Dongxin Automation Technology Co., Ltd. – Over 15 years of hands-on experience in cable machinery design, assembly, and commissioning)

Hello, I'm Engineer Li from Dongguan Dongxin Automation Technology Co., Ltd. (dxcabletech.com). Since joining the company in its early days back in 2009, I've personally overseen the complete lifecycle of hundreds of extrusion machines – from initial part inspection to final delivery and customer startup support. In a small-to-medium cable equipment factory like ours, every machine is built with care because we know our customers rely on it for continuous, high-volume production runs of 8–12 hours per day.

Today, I want to walk you through the real, step-by-step process of how we build one typical cable extruder . This isn't marketing fluff or a generic video script – it's exactly what happens every day in our Dongguan workshop. By sharing this openly, we aim to demonstrate our deep expertise, the rigorous quality controls we apply, and why customers trust us to deliver reliable equipment that minimizes downtime and scrap.

Phase 1: Incoming Parts Inspection & Quality Verification (The Foundation of Reliability)

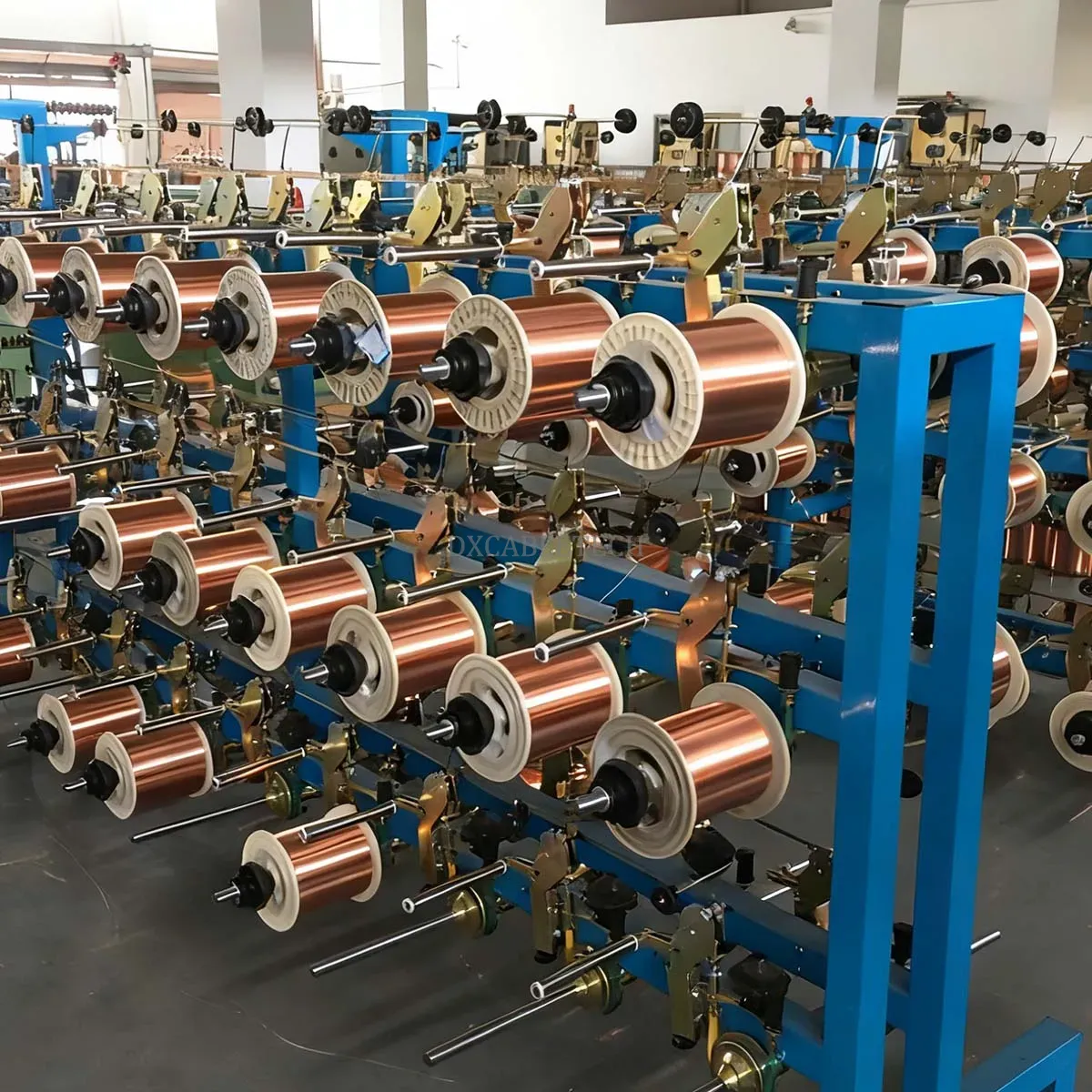

Everything starts when components arrive at our loading dock. A single extruder can involve 500+ parts: screw & barrel sets, gearboxes, motors, heating bands, PLC panels, dies, feeders, cooling troughs, and more.

What we do first: Unpack and perform 100% incoming inspection. Core items like the extruder screw (nitrided 38CrMoAlA steel) and barrel are measured with digital calipers and micrometers – we enforce tolerances as tight as ±0.01 mm on critical diameters to ensure long service life and uniform melt flow.

Electrical & mechanical checks: Variable frequency drives (e.g., from Siemens or Delta), temperature controllers, and sensors are powered up and tested individually. Any component showing signs of rust, damage, or out-of-spec performance is rejected immediately and returned to the supplier.

Why this matters: In 15+ years, we've learned the hard way that skipping even one faulty bearing or heater band can cause overheating, melt fracture, or complete shutdown after just a few weeks of customer use. That's why every inspected part gets a stamped QC report – traceable back to batch and supplier.

Phase 2: Precision Assembly – Where Experience Makes the Difference

Assembly typically takes 3–5 working days per machine, depending on model complexity.

Day 1 – Base & Frame: We weld and level the heavy-duty steel frame using laser alignment tools to achieve flatness better than 0.05 mm/m. This prevents vibration issues that plague poorly assembled machines.

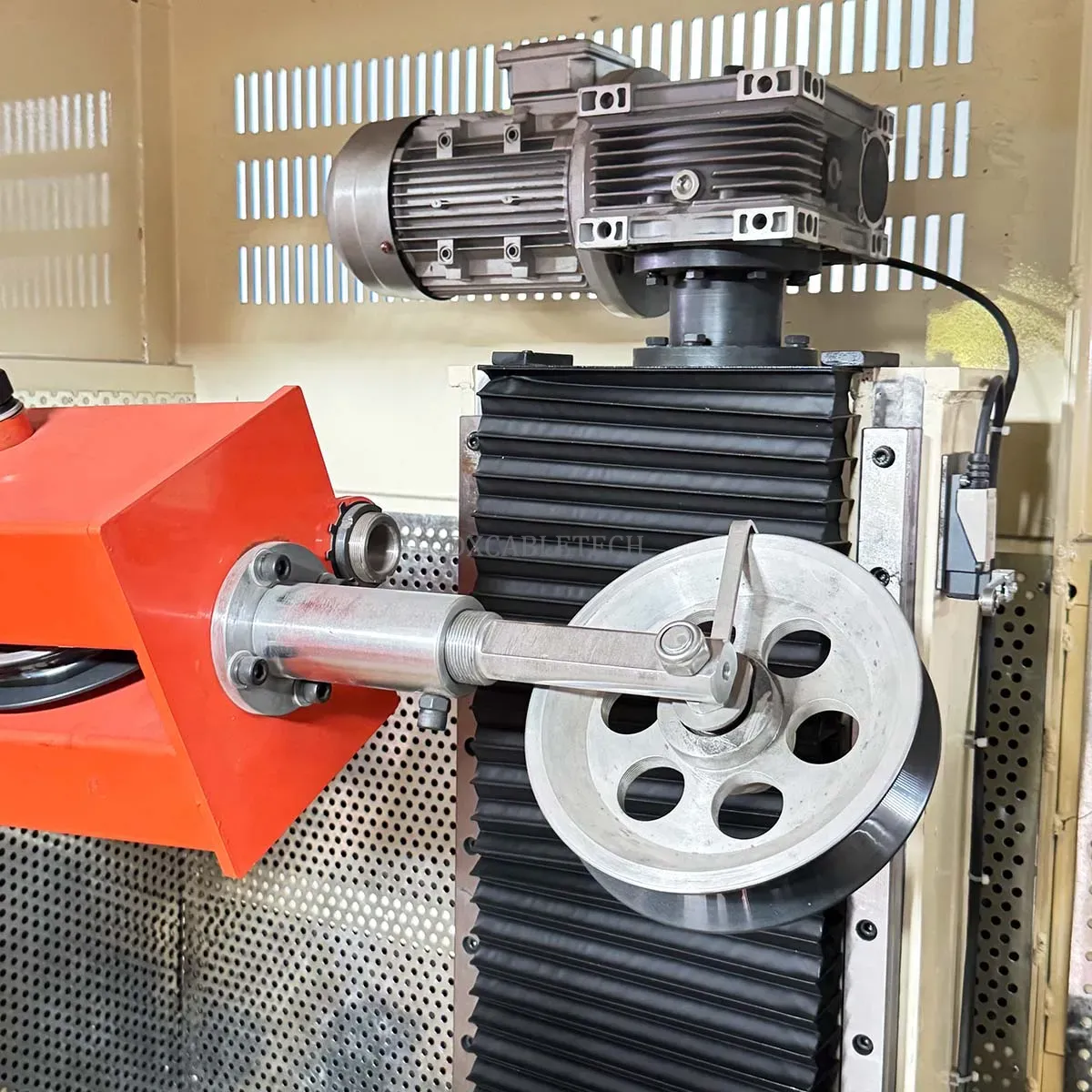

Day 2 – Core Mechanical Integration: Install the extruder barrel/screw assembly, thrust bearing, gearbox, and hopper feeder. The screw-barrel concentricity is adjusted multiple times with laser alignment instruments until we hit >98% alignment – this directly impacts output consistency and energy efficiency.

Day 3 – Electrical & Control Systems: Full wiring of the control panel (using color-coded cables for easy maintenance), installation of HMI touchscreen, and loading of our pre-configured PLC program templates (customized for common cable types like building wire, power cable, or data cable insulation).

Responsibility system: We assign one dedicated technician per machine from start to finish. If any issue arises post-delivery, that person is accountable – this creates real ownership and pride in the work.

Phase 3: Extensive Testing & Commissioning (Proving It Works in Real Conditions)

No machine leaves our factory without thorough validation.

Empty run (no material): 24–48 hours continuous operation to monitor vibration (using portable analyzers), bearing temperatures (must stay below 60°C), noise levels, and overall stability.

Material trial run: Load standard PVC/PE pellets and extrude sample profiles. We measure output rate (kg/h), melt pressure, current draw, surface finish, and wall thickness uniformity. Data is logged and compared against our design specs – any deviation >5% triggers disassembly and re-adjustment.

Customer-specific simulation: If the order includes custom dies or special compounds (e.g., low-smoke zero-halogen), we run trials with the exact material provided or simulated equivalents.

Final QC sign-off: Full test report generated, including photos of sample extrudates, data logs, and video of the machine running smoothly.

This rigorous testing phase is why our machines often start producing good cable within hours of arrival at the customer's factory – we simulate real production stress before you ever see it.

Phase 4: Safe Packaging, Documentation & Shipment

Protection: Main body coated with anti-rust oil, wrapped in plastic film, and crated with wooden/steel reinforcement. Vulnerable parts (dies, tools, spare heaters) packed separately.

Complete documentation package: User manual (English/Chinese), maintenance schedule, electrical schematics, parts list, 1-year warranty certificate (extendable on core components), and full QC/test reports.

Transparency: We take timestamped photos and short videos of the packed machine and provide them to the customer upon request – full traceability from our side.

In the past 12 months alone, we shipped 28+ extrusion lines with zero return-for-quality issues. That's not luck; it's the result of consistent processes built over 15 years.、

Why We Share This “Behind-the-Scenes” View

As a mid-sized manufacturer in Dongguan, we don't have massive marketing budgets or celebrity endorsements. What we do have is real factory experience, a team that's been building cable machinery since 2009, and a commitment to delivering equipment that actually performs in tough production environments. By showing you exactly how we build every machine, we hope to build trust: we understand cable production pain points because we've lived them for over a decade.

If you're evaluating extrusion equipment for your cable line – whether for power cables, automotive harnesses, data/communication wires, or specialty applications – you're welcome to visit our factory, watch a machine being assembled, or request a live video call during testing. We're an open-book company.

Ready to discuss your needs? Click the “Get Quote” button

We don't just sell machines – we help you solve real production challenges with reliable, proven equipment.